Stanley Bench Planes Mini-Site Navigation

Type 6.

Planes made by Stanley 1888-1892.

Type 6.

Planes made by Stanley 1888-1892. - All of the features of the previous, except:

- Lateral adjustment lever now is a two-piece construction, with a circular disk replacing the straight portion at the point where it engages the slot in the iron. "7-24-88" is also stamped into the lever, with the rest of the dates, as before.

- The brass adjusting nut now has a left-hand thread.

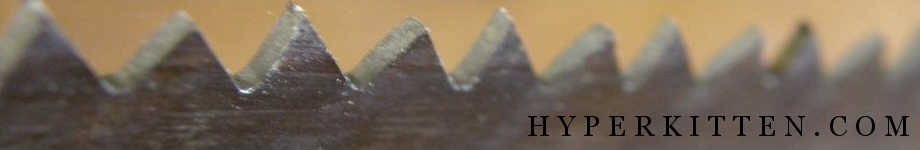

- New iron design, where the circular hole is now located toward the

cutting edge, instead of the top. Stanley claimed:

"The improved form of this Plane Iron renders it unnecessary to detach the Cap Iron, at any time, as the connecting screw will slide back to the extreme end of the slot in the Plane Iron, without the danger of falling out. The screw may then be tightened, by a turn with thumb and finger; and the Cap iron will serve as a convenient handle, or rest, in whetting or sharpening the cutting edge of the Plane Iron."

There you have it, in all its gorey, why the circular hole was repositioned, after it being at the top of the blade for some 100 years. At least that's how Stanley decribed the change. However, the patent drawing for the change shows what I believe is the real reason for the change - the circular disk, on the lower end of the lateral adjustment lever, loses its ability to engage the slot provided for it (in the cutter) when the iron is nearly used up. By relocating the circular hole toward the bottom of the cutter, the iron can be used right up to the slot, without sacrificing the advantage gained from the lateral adjustment lever.

- Bead eliminated from the front knob.

- Frog receiver has two shallow grooves, parallel to the plane's sides, cast into it. The screw holes are located in the grooves.

- "STANLEY" "PAT. AP'L 19, 92" (in two lines) stamped on the iron. The original type study doesn't mention this, but some of these irons can be found with just "STANLEY" and not the patent date.

Click here to go the Plane Feature Timeline for this type.